Updated: April 16, 2025

Warehouse management is often one big balancing act – ensuring there is enough inventory (but not too much!), keeping inventory secure from theft (but easy to access!) — all within a compact footprint. From navigating global labor shortages to maximizing every square foot of storage space, today’s operations demand a more agile, data-driven approach.

In this expert guide, you’ll find 55 proven warehouse management best practices designed to optimize organization, improve space utilization, boost productivity, enhance safety, and sharpen inventory control. We consulted some of the industry's brightest minds and have updated this piece to for its 5th anniversary.

Whether you're scaling up, streamlining, or just staying competitive, these practical tips will help you build a smarter, more resilient warehouse.

Warehouse Productivity Best Practices

1. Review SKU Velocity Regularly

Some SKU’s move faster than other. Consistently review SKU velocities and relocate SKUs that have moved from fast to slow, or vice versa. Ensure fast moving, popular SKUs are kept in an accessible and ergonomic location (end of aisle at waist height). Consider storing SKUs frequently picked together as a kit.

2. Store Products in Bins and Totes

Products left on open shelving are exposed to contaminants such as dirt, dust, and exhaust fumes from forklifts. Using bins, dividers, and totes not only keeps products clean, organized, and in usable condition, but also maximizes your storage capacity. You might also consider storing inventory in an enclosed automated storage and retrieval system (AS/RS) such as a Vertical Lift Module (VLM) or Vertical Carousel Module (VCM).

3. Consider a Pick and Pass Strategy

Order totes travel from zone to zone for fulfillment. Each picker works to fill SKUs only in their zone, passing the order tote to the next zone when completed. Once the order has gone to the last zone, it reaches shipping and is sent out for delivery. To add to your productivity gains, pick the orders into a shipping container, so these orders can be labeled and put onto a truck once picking is complete.

4. Implement Batch Picking for Faster Order Fulfillment

Batch picking allows one picker to fulfill multiple orders, or a batch of orders, simultaneously, visiting each SKU location one time. This picking strategy reduces travel time to the same pick location multiple times a day, which in turn increases picking productivity.

5. Speed Order Fulfillment with Parallel Picking

In a parallel picking strategy, pickers are assigned to a specific zone and they are responsible for picking the SKUs in their assigned zone. Each zone picks the SKUs required from their zone simultaneously (in parallel). Once the SKUs from the zone are picked, they are sent to a consolidation area where SKUs from each zone are married up to complete the order. This strategy allows for more orders to be picked at one time, speeding up order fulfillment.

6. Calculate the Cost of Labor

Calculate the cost of labor to ensure a true cost balance in your operations. Are you constantly putting more bodies in your picking system? Spending too much money on worker comp claims? An investment in automated storage can reduce the amount of people you need in your picking operation, allowing you to reassign them elsewhere.

Read more in our White Paper: Calculating the True Cost of Labor

|

“Too often, labor costs are treated as fixed when they should be flexible. Automation helps shift that mindset by allowing teams to work smarter, not just harder.” |

7. Receive Product Directly into Open Orders

Instead of receiving an order and restocking it to a storage location, receive the product against an open order waiting for the product to be received. This means, the product is never really received into the warehouse inventory just to be picked, it is received directly into an order and goes right back out the door.

8. Prioritize Orders with Wave Picking

Consider using wave picking to prioritize which orders are picked first and keep operations flowing smoothly. Releasing orders in waves helps manage the workload on each function (picking, order consolidation, replenishment, packing, shipping) to not overload one function creating a bottleneck.

9. Sequence Picking to Increase Productivity

Create a clear path to productivity with sequence picks that reduce travel time. Sequence picking doesn’t require a picker to crisscross a picking zone or visit a storage location more than once to fill an order. Reducing this repetitive work increases productivity and eliminates unnecessary walking.

10. Replenish Regularly to Reduce Short Picks

Every team needs someone ready to step in, which is why your warehouse should prioritize replenishment. Prioritize it to reduce short picks and to reduce overflow in the receiving area. Instead of leaving new product at the receiving door, find times for your operation to fit replenishment in throughout the day. This will eliminate sending out orders which are short a part or two, when in fact you had those parts in your facility the entire time!

11. Design Your Facility with Flexibility

Flexibility means being prepared for change. Design your operations to be managed by few employees and easily increased to many employees at peak times. This will help you plan ahead for anticipated seasonal demand when you know you need it, not when it’s too late to find the labor.

Ready to turn these tips into an action plan? Download our comprehensive warehouse management guide - newly updated for its 5th year anniversary. This extremely popular guide has been downloaded more than 70,000 times and has been translated into 11 languages. Get your copy now.

Inventory Management Best Practices

12. Protect Products from Theft

Deploy inventory control to prevent theft and misplaced SKUs resulting in part shortages. Using inventory management software to monitor transactions, posting cameras in open rack and shelving areas and simple locks on cabinets and drawers can save you in the short term and in the long run. For high dollar value SKUs, consider using RFID to track down their location and find the culprit.

13. Match SKUs to Proper Storage Method

Group inventory (by SKU velocity or size) and match SKUs to proper storage method. Perhaps you have some bulky, fast moving goods, those might belong on shelving in a front pick zone. Whereas your small sized, medium movers might belong in automated storage technologies. Matching your SKUs to the proper storage method is only going to improve your warehouse efficiencies.

14. Prevent Part Shortages with Minimum Reorder Quantities

Set minimum quantity and reorder points to prevent part shortages, with automatic reporting to purchasing. For companies who use the just-in-time (JIT) method, the last thing you need is to discover you are out of the part you need, right now! If you set minimum reorder quantities, you can track your inventory levels regularly and automatically receive the new parts you need when you need them!

15. Implement an Inventory Handling Process

Implement an inventory handling process which best fits your business practices. Common practice is FIFO, or “first in, first out”, but it is not necessarily for everyone. Most often, FIFO is beneficial for companies looking to rotate their inventory so the goods stored don’t expire or reach end of life before they are used. However, LIFO, “last in, first out”, works well in certain environments.

16. Use Weigh Scale Counting

Who wants to count all of those small nuts and bolts anyways? Weigh scale counting is a simple process to implement and will increase productivity and reduce counting errors.

17. Consider Cycle Counting Regularly

No one likes a control freak – unless they manage inventory! Keep track of inventory counts on a regular basis to ensure accurate levels and avoid a timely and costly year end physical inventory. Whether you cycle count monthly or quarterly, if you are keeping track of your inventory throughout the year, it will save everyone the hassle. You can thank your control freak for this one!

18. Have a Documented Returns Handling Process

There will, of course, be returns. Have a clear and documented returns handling procedure to avoid bottlenecks at receiving and restocking as well as the clutter which can pile up from an overflow of returns.

19. Plan Your Facility for Scalability

Don’t be spontaneous when it comes to your facility! Learn to become a planner when it comes to your business. Plan for flexibility and scalability. Investing in racks of shelving today might make sense…today. But 5 years from now, you might find your product line changing or you downsize due to a new lean process. All that shelving isn’t necessary now is it? Have long term plans and goals so you can accommodate future growth easily, without a major headache or last minute investment.

Warehouse Organization Best Practices

20. Utilize Vertical Height to Recover Wasted Space

Look up - you see the unused ceiling height? That’s wasted money. Consolidate your overall footprint and maximize your square footage by implementing automated storage and retrieval systems. Automated storage and retrieval systems are designed to utilize the floor to ceiling height recovering up to 85% of otherwise wasted floor space.

21. Maximize Storage by Reorganizing

Rearrange your shelving to reduce the amount of space between each shelf and store similar height products on the same shelf, creating more storage space. For even greater cube density, consider an ASRS for maximum storage density that automatically adjusts to your changing product mix.

22. Review Your Facility Flow Often

Review the facility flow to make sure it flows in one direction from receiving, to stocking, to picking to shipping – you don’t want people wasting time zig-zagging from area to area. Once you find the flow which makes sense for your facility, you’ll be running in tip top shape.

23. Lean Your Inventory

Lean your inventory to align with JIT practices while keeping enough JIC (just in case) inventory onhand. Only keep what is essential on site to reduce overstocking inventory. This will keep your warehouse operating at high efficiency and deliver the service your customers expect.

Learn the difference between a JIT (just in time) inventory strategy and a JIC (just in case) inventory strategy - and when to use each one!

24. Keep Aisles Clear

Clear aisles of all clutter allowing easy access to stored SKUs and preventing injury. Ensure product is organized and quickly accessible - don’t let employees waste time searching for the one ladder in the facility – the ROI is in the increased productivity.

25. Optimize Aisle Space for Forklifts

Design your facility with enough aisle space for forklifts to travel easily. However, don’t give them too much room or you’re wasting valuable space. Find the “just right” spacing to be productive but not wasteful.

26. Calculate the Cost of Space

Are you making the best use of every square foot you’re paying for? Consider the benefits of implementing high density dynamic storage and retrieval technologies to consolidate your storage areas and recover wasted space, expanding your footprint without a brick and mortar expansion. This will leave you so much room for activities!

|

"Rent keeps rising, but your ceiling isn’t. When you use vertical space more effectively, you create capacity where it already exists—no construction required." |

Read more in our White Paper: Calculating the True Cost of Space

27. Keep Workspaces Clean

Keep all workspaces clean and free of clutter to prevent damage of inventory and potential loss of product. This will make your customers, and your co-workers, happy.

Warehouse Picking Accuracy Best Practices

28. Implement Pick to Light Technology for Increased Accuracy

For an illuminating approach to picking, pick to light technologies can show the way. Pick to Light technologies direct pickers to the exact location of the SKU for increased accuracy. Light-directed technologies take the guessing out of picks or puts. Lights can pinpoint a location to pick from, or tell the exact SKU number and quantity to pick, eliminating picking errors and increasing accuracy to 99.9%.

29. Consider Color Picking for Increased Efficiency

For a productivity boost in existing zones or pods of automated storage and retrieval units, implement color picking to allow multiple pickers to pick orders in the same zone simultaneously. It’s pretty straightforward – pickers follow their assigned color lights directing them from machine to machine batch picking orders as they go.

30. Reduce Picking Errors with Automation

We all make mistakes but it’s important to know how to recover. Mispicks cost you time and money, and can damage your company reputation. Consider implementing automated storage and retrieval systems integrated with light-directed picking features which can eliminate human error.

Read more in our White Paper: Calculating the True Cost of Accuracy

Warehouse Safety Best Practices

31. Integrate Ergonomic Hoists for Heavy Lifting

In a warehouse, workers pick things up and put them down, all.day.long. Make it easier for your employees to lift heavier product by integrating ergonomic hoists and lifts. (Let them bulk at the gym, not on the warehouse floor.) This will improve worker ergonomics and reduce worker compensation claims.

32. Use Signage to Stay Organized

The proper signage and labels can keep your warehouse moving forward. To direct people and stay organized, make sure your signage is clear and easy to understand. In addition, consider posting floor maps to provide additional information for visitors. This can help you avoid accidents and major cleanups.

33. Store Frequently Picked SKUs Together

Store SKUs frequently picked together in the same picking location to reduce travel and search time for the picker. This eliminates visiting the same pick face multiple times a day, increasing worker productivity.

34. Employees Are Your Most Important Asset

Employees are your most important asset so give them a great work environment that will aid in retention. Touch base with them frequently to make sure they understand their roles and are comfortable with them. Meanwhile, job shadowing can help you determine if someone would be better suited in a different position.

35. Provide Training Certifications

Provide proper certifications for all necessary staff to ensure everything is being operated by trained, skilled and certified professionals to reduce the risk of injury, workers compensation claims and safety violations.36. Improve Processes to Increase Productivity

Take a look at your processes to determine where you can improve. Minimize product touches, reduce wasted steps and re-allocate the time spent doing these activities elsewhere for a more productive outcome.

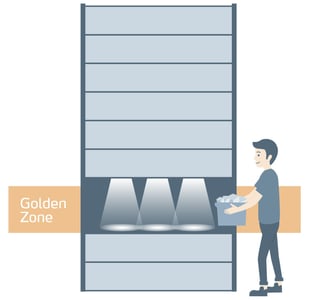

37. Implement Ergonomic Pick Locations

Reduce bending and reaching by organizing products in the golden zone, the area between the waist and shoulders. This improves worker ergonomics, increases picking productivity and reduces employee backaches.

38. Reduce Wasted Walk and Search Time

Employees reaching their Fitbit step goals during their work shift – good for them, not so good for you. Fit your employees with pedometers, or a much cooler tech-y gadget, to document their steps and walking time – then find ways to reduce that wasted time. No one likes an overachiever.

Software - Warehouse Best Practices

39. Utilize Data to Make Decisions

WMS, WCS, ERP – so many acronyms… but when you link the systems together real data starts to emerge. Gain real time insight into your entire operation by connecting data across multiple platforms so you can start making data driven operational decisions.

|

"You can’t manage what you can’t measure. Real-time data takes the guesswork out of warehouse operations and puts you in control" |

40. Go Paperless

No one wants to manage paper pick list anymore – it’s tired, old fashioned and error prone. Reduce or eliminate paper whenever possible, using technology for a mobile and environmentally friendly worker experience.

41. Utilize a Label Printer to Track Inventory

Integrating a label printer to bag and tag parts can increase stock and order accuracy. Parts can be tagged with part number, lot number, serial number, batch number – all the numbers. Consider bagging and tagging your parts to track the inventory throughout its life-cycle, and make customer returns easier.

42. Easily Identify Items with a Parts Picture Database

Utilize a parts picture database to increase pick accuracy. It’s easier to identify items by photo rather than by a ridiculously long part number or difficult part name. Instead, take photos of your inventory to pick by photo instead of by part number. This will increase picking accuracy, reducing mispicks and making everyone’s lives easier.

43. Use Inventory Management Software for Traceability

Use traceability to determine the exact part accessed by an operator with a time stamp. Using inventory management software, it’s possible to monitor AS/RS operators as they pick parts. This traceability is important for industries who use tools in CNC machines for example. They are able to determine when a tool was picked from a unit and what person took it in case they need to track down this particular tool.

44. Implement BarCode Scanning for Increased Accuracy

Using a barcode scanner for quick and accurate picking/putting eliminates the guess work. Confirming an item during the picking process, by simply scanning it, ensures order accuracy from the beginning.

45. Maximize Cube Density with Automation

Maximize cube density automatically with the push of a button using intelligent software. As your business grows, products evolve and inventory expands. With changing inventory profiles, it’s critical to manage cube density within every storage device. Shuffle the storage locations to get the most out of your storage space (use the automatic “tray shuffle” in your VLM).

46. Use Statistics to Increase Productivity

Create a friendly competition among workers using operator performance statistics from your material handling software. For example, Kardex Power Pick System inventory management software can monitor and record the number of picks per operator , the time per pick and accuracy rates. Analyzing the productivity of workers using ASRS can confirm you’re highly productive or it can show where you could make some productivity gains and improvements.

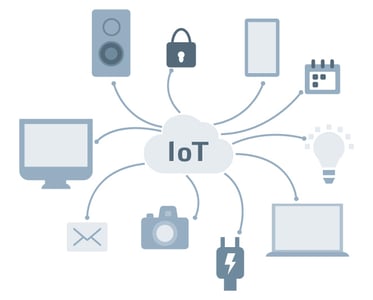

47. Connect Warehouses with IoT

Utilizing the internet of things (IoT), you can connect your warehouses to control all of your inventory from one location. The ability to monitor your inventory and storage technologies remotely can result in reduced downtime and higher efficiencies.

48. Keep Track of High Dollar Inventory

Track high dollar or sensitive items by serial, lot and batch number throughout the receiving, stocking and picking process. This is especially important for the medical device manufacturing industry for example. When picking a knee replacement, it is important to know which serial, lot and batch number is in each order in case of a recall.Warehouse Maintenance Best Practices

49. Plan for Preventive Maintenance

It’s in your best interest to adhere to the manufacture's maintenance schedules they recommend. Make the maintenance of your equipment a priority, it keeps your facility in working order reducing or eliminating unplanned downtime. Often, the extended warranty is worth it.

50. Keep Spare Parts on Hand to Reduce Downtime

Technology and equipment failures are everyone’s worst nightmare. In an effort to keep you daydreaming in the warehouse, keep spare parts on hand in case of those failures. This should allow for a quick repair and get you back up and running in no time, reducing unplanned, extended periods of downtime.

51. Evaluate Technology for Maximum Efficiency

Technology, that is. Task someone to keep abreast of the changes in the technologies you use in your operations. Evaluating the benefit of technology add-ons throughout the life-cycle of your equipment can further improve your efficiencies.

52. Perform Process Audits Often

Perform a process audit of your material handling and picking operations yearly to ensure you are getting the maximum benefit of your technology. Are there processes you can tweak for efficiency? Are there modules of software you have access to but don’t use? Material handling technology should be driving your operations forward, be sure you get the full value out of your investments!

Warehouse Shipping and Receiving Best Practices

53. Optimize Your Consolidation Zone

If you implement a parallel zone picking strategy, be sure to optimize the consolidation area where all of the products in an order come together to party in their shipping container. Consider the consolidation area as its own zone, leave room for order totes to be received at consolidation and for the empties to be returned for future orders. Clean and organized, remember?

Learn more about implementing order consolidation.

54. Consider Picking Straight to a Shipping Container

The less a product has to be touched, the more efficient the process. Picking straight to a shipping container saves time and eliminates unnecessary steps. Instead of picking to an order tote which moves with the order to shipping only to take all of the items out to put them in a shipping container, change the process. Pick directly into a shipping container, promoting lean processes and reducing the steps in your order picking strategy.

55. Review Receiving Process

Review your receiving process to ensure items are properly inspected, counted, and verified before entering them into the inventory management system. Don’t allow unacceptable and damaged items into inventory.

Ready to turn these tips into an action plan for your warehouse? We've got you covered. We've compiled these tips (and so much more) in our complete Warehouse Best Practices Guide. Trusted by more than 70,000 people and translated into 11 languages, this incredibly popular how-to guide is a must-have for warehouse managers. Get your copy now.

Here what 25 experts say about Warehouse Automation Trends Coming Your Way in 2025