Lastly, Review The Fulfillment Process

Once you’ve successfully determined which inventory goes into which storage technology, consider the minor enhancements you can make within each category. This includes but is not limited to adding pick to light technology, upgrading the inventory management software, adding bar code scanning, integrating a hoist for heavy lifting, etc.

Focus here specifically on how each inventory category will be received, inventoried, stored and retrieved from the selected technology. Are there small adjustments you can make to make the process better? Sometimes a small investment will go a long way toward overall operations efficiency.

- Productivity – what manual steps can be cut to make the order picker faster?

- Space Savings – can storage locations within the storage technology be better utilized?

- Throughput – how can product be delivered faster, or located faster by the order picker?

- Accuracy – is there an opportunity for a technology addition that can increase accuracy?

- Ergonomics – is inventory available to the picker at an ergonomic position?

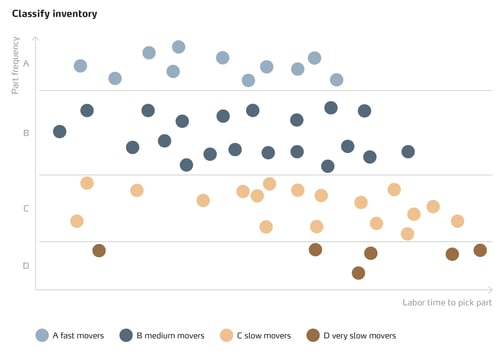

And when all is said and done, don’t forget about slotting and re-slotting SKUs. It’s critical to review inventory on a regular basis to maintain efficiencies. Read more about slotting here.

Case Study: SKU Velocity Profiling

Kubota’s parts distribution center in Ontario, Canada implemented a zone picking strategy with six Horizontal Carousel Modules, four Vertical Lift Modules and racking to double productivity and recover 83% floor space.