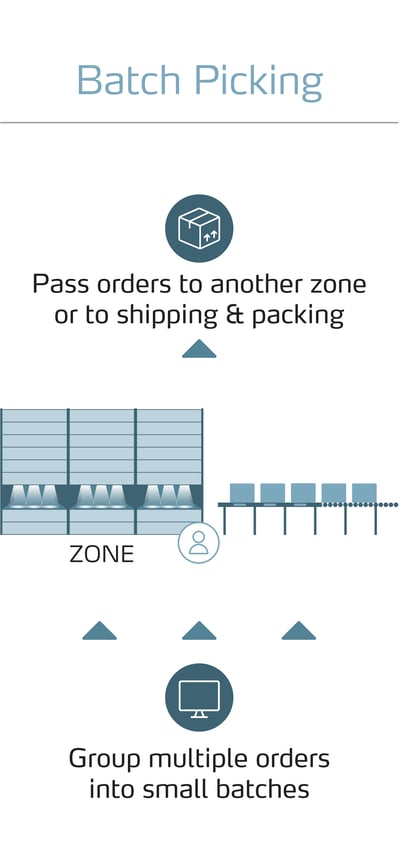

Using Batch Picking with Automation

The same batch order picking concept applies to an automated order fulfillment operation. The zone is typically setup with at least two automated storage units arranged next to each other with a batch picking station 6- 8 feet in front of the access openings. The operator works in the middle.

The operator can manually select the orders to batch from the software. More often, the software automatically creates the batch of orders based on order profile (SKU commonality), customer delivery date, shipping carrier cutoff time or another predetermined criteria.

Once the batch of orders is created within the software, the operator now needs to setup the batch picking station. Each order location on the batch picking station is fitted with a put light to direct the operator during picking. To start the batch picking process, the operator uses a bar code scanner to scan the batch station location and the order tote or box, matching or marrying them within the software. Now the software knows the put location of each order.

When ready, the operator initiates the automated storage devices to retrieve and deliver the SKUs required to fill the order batch. The first SKU is delivered to the operator and a pick light illuminates on the storage device directing the operator to pick a specific quantity. The operator picks the quantity as directed, and pushes a confirm button. They then turn to the batch station to the waiting put lights and distribute the first SKU among the waiting orders. As the SKU is added to each order, a confirmation button is pushed to indicate SKU was placed in the waiting order. When all SKUs are distributed among the batch of orders, the operator turns back to the storage units to pick the next SKU needed for the order batch.

As the first machine is working to retrieving another SKU, the second machine has the next pick ready so the operator is never waiting. This is the reason for two machines in the work zone, to ensure the operator is rarely, if ever, waiting on product to be delivered. With proper SKU slotting, wait time should be minimal.

The operator picks in this round robin style until all SKUs for the order are filled. The order is then pushed off onto conveyor or the batch picking cart can be manually rolled to the next area for fulfillment or directly to shipping. In pick and pack operations, instead of batching the items into an order tote, you can pick orders directly into a shipping tote.

Batch Picking for Speed

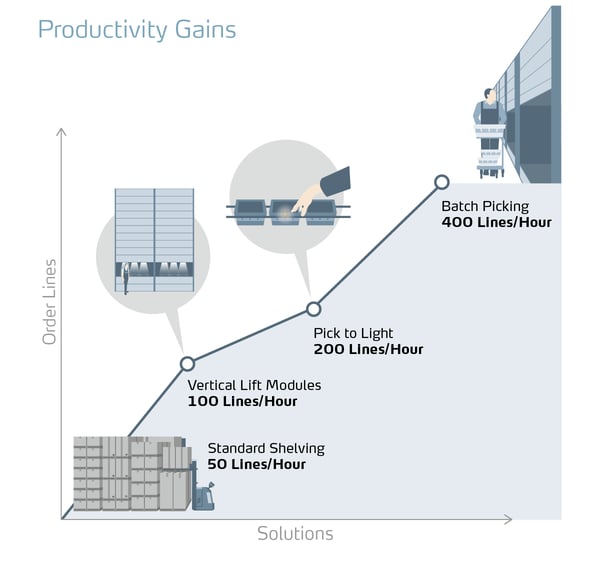

Now that you know what it is, why the heck would you use it? Speed! The main benefit of batch picking is the increased throughput rates you can achieve. What kind of rates? Glad you asked. Throughput rates are always application dependent (what sized parts are you picking?, are you bagging and tagging?, is there a pick verification step?, etc.…). Generally speaking you can achieve about 50 lines per hour per person from a standard rack and shelving layout. Moving inventory into automated storage and retrieval systems will double your throughput. Add pick to light technology to double it again (and increase accuracy), and finally incorporate batch picking to reach about 400 lines per hour. But the fun doesn’t end there – if it’s faster picking you need, consider more advanced strategies such as color picking or cross picking.

Case Study: Value Drug Mart

Not sure if batch picking is a good strategy for your operations? Check out this real life example of a distribution center using batch picking at their facility.