5 Pick to Light Technologies

Pick-to-light systems can be integrated into virtually every kind of storage and picking system - from static shelving and pallet rack to automated storage and retrieval system (AS/RS) such as Vertical Buffer Modules, Vertical Lift Modules, Vertical Carousel Modules and Horizontal Carousels. They’ve been documented to deliver at least a 50% increase in pick rate productivity, and accuracy rates of up to 99.9%. Operators often report picking by light is like playing a video game—and much more fun than picking by paper!

There are several different types and styles available to match to different operations’ picking processes and storage systems. Here’s a brief overview of a few options and how they can be used.

1. LED Pick-to-Light Technologies

LED pick-to-light systems are designed to simplify human order picking by using LED pick lights to improve picking efficiency, picking accuracy, and process reliability. Used most often in combination with Vertical Lift Modules & Vertical Carousel Modules, the LED panel is mounted at the pick face to guide the operator through the picking process.

The LED panel directs the operator to the exact location of the part to pick and displays material and order information such as part number, description, and order quantity. Order accuracy is increased and mispicks are reduced. Often language can be customizable for multilingual communication.

Read More: Display LED Navigator

2. Pick-to-Light & Put-to-Light (Batch Lights)

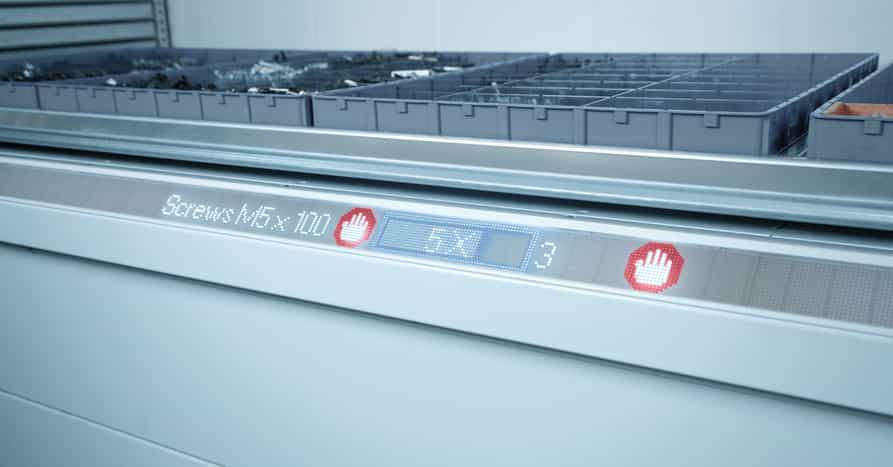

Used with Horizontal Carousel Modules, Vertical Carousel Modules, Vertical Lift Modules, static pick faces, shelving, mobile picking carts and cubby-hole putwalls, these pick to light modules direct an operator to pick items from (or put items to) a specific location.

Pick-to-light modules illuminate (and often blink) to indicate where the pick is stored, and often display the number of items required to pick; after the required action is complete, the operator presses a confirmation button on the module to confirm the pick (they can also indicate replenishment quantities and destinations). The same type of lights are known as put-to-light or batch lights when used for batch picking to totes or carts, and for picked item sortation and order consolidation at stationary workstations.

3. Light Pointer Technologies

Used exclusively with Vertical Lift Modules and Vertical Buffer Modules, this system deploys an LED or laser light mounted from above the pick area. Software-driven, the pointer swivels to project its light beam into the storage tray or bin and point to the location of the required item, eliminating search time in picking or replenishment.

4. Position Indicator Light Bar

Incorporated into the access openings of both Vertical Lift Modules and Vertical Carousel Modules, these LED lights illuminate in alignment with the position of the required item where it is stored in the tray.

5. Pick-to-Light: Light Tower

Integrated with Horizontal Carousel Modules, this unit houses picking display modules in an upright (tower) configuration that aligns to the carousel’s stacked storage bins. The displays indicate the active carousel, shelf level, cell location and quantity to pick. Software-driven, a single light tower serves two horizontal carousels working together in a picking pod.

Which pick-to-light technology is right for you?

As always, it depends on the application and the importance of speed and accuracy in your operations. Evaluate your warehouse requirements, budget constraints, and operational workflows to determine which pick-to-light technology aligns best with your needs.