Batch Picking and Cross Picking to Enhance Performance Further

To further improve your overall picking performance, consider the following picking methods as enhancements to the picking strategy you’ve chosen.

- Batch Picking: This is where orders are grouped together into batches to increase picking productivity. Batch picking requires a storage method, a batch station and inventory management software that manages the batch picking process.

For a Deeper Dive: How to Implement Batch Picking in Your Warehouse - Cross Picking: Cross picking combines two batch picking work zones for increased productivity. The concept is simple: Two automated pick zones — comprised of Horizontal or Vertical Carousel Modules or VLMs — are positioned face-to-face. In the middle of the two pick zones is a batch station consisting of a side-by-side roller conveyor with a series of alternately angled flow racks (also called slides) on top. Atop the conveyor and beneath the slides sit two rows of order totes, back-to-back — one for each pick zone. The entire system is light-directed.

For a Deeper Dive: What is Cross Picking in a Warehouse?

Technologies to Improve Order Picking Accuracy

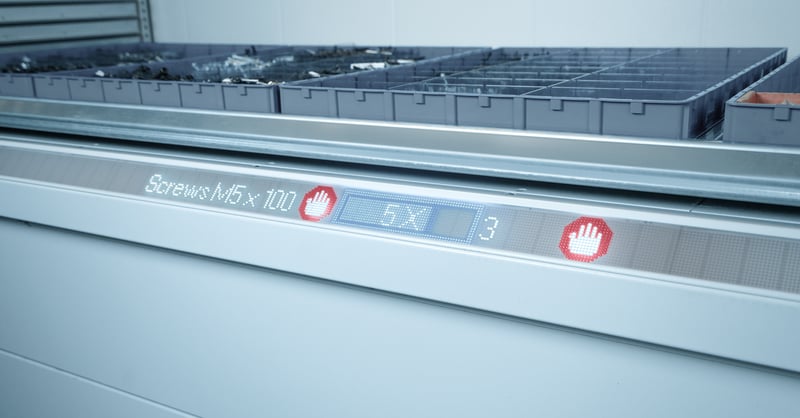

Now remember those business objectives I mentioned? There are additional tools to further improve your inventory accuracy within these strategies. Pick to light technology comes in handy when you want to increase accuracy. From transaction information centers using LED lights to display part name, number and quantity to pick, to light pointers directly pinpointing the item to pick within an AS/RS, pick to light technology can increase accuracy by up to 99.9%.

Also, using a bar code scanner to confirm a pick before placing it into an order tote can ensure the worker has picked the correct item before it ever leaves the facility.

In closing...

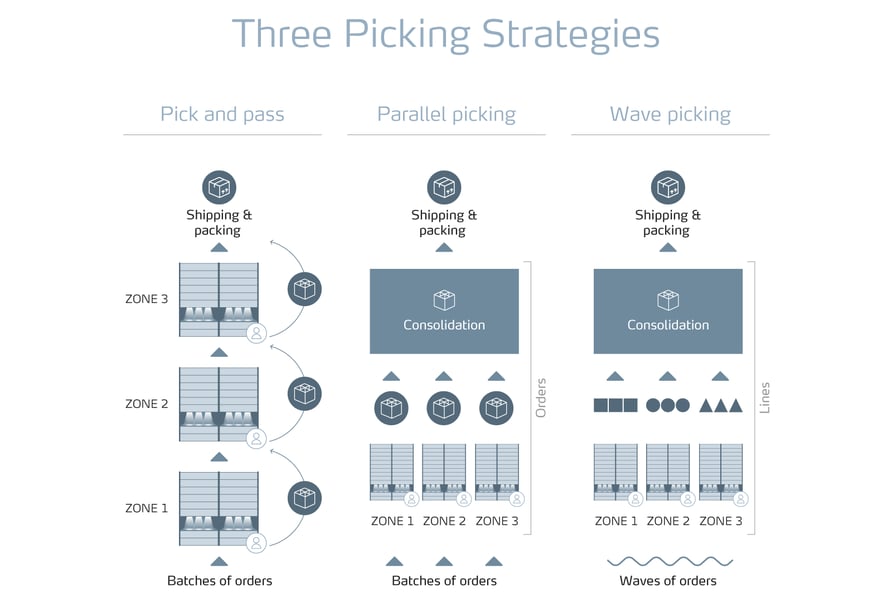

Review your facility layout. It is important to organize your facility into zones to support these picking strategies. Zones are most commonly created based on SKU type or SKU velocity to create pallet, case and forward pick zones. Zones may be determined by physical storage or handling characteristics, fast/medium/slow moving lines, security or hazardous considerations and different temperature or climate controlled requirements.

Often each zone has a different type of storage technology to most efficiently handle the SKUs in that zone – from flow rack, Vertical Lift Modules (VLMs), Vertical Carousel Modules, Horizontal Carousel Modules, mini loads, multi-shuttle systems to standard rack and shelving. This is the foundation for your picking strategy performance. Keep in mind, you will see the biggest performance gains when you enhance your picking strategy with one of the additional methods or technologies we’ve outlined.