Read More - "What's Right for You?": Vertical Lift Module vs. Vertical Carousels | Vertical vs. Horizontal Carousel Modules

Bin and Tote Delivery ASRS Technologies

#4 Crane-Based Mini-Load AS/RS

Mini load systems handle loads with ease. With a single, crane-mounted load handling device dedicated to each extremely dense rack aisle, mini-loads handle products in cases, totes or trays. The cranes travel either on rails or wheels with fast acceleration speeds to deliver product to the operator via a workstation located at the end of the aisle.

The rack in a mini-load can provide single or double deep storage. The average weight per location is around 100 pounds in a single deep location and 200 pounds in a double deep location. Ideal for slow moving items, single deep mini-loads are capable of delivering 1 load per minute, for throughput rates of 60 to 100 lines per hour, while double deep mini-loads can deliver 2 loads at a time to achieve 120 putaways and 120 picks per hour. If you’ve got 10,000 plus totes or over 25,000 SKUs to store, this is a great high-density storage solution.

#5 Vertical Buffer Modules (VBMs)

The vertical buffer module is a bin handling system designed for smaller applications (under 10,000 totes or 25,000 SKUs) that often can’t cost justify a large, expensive system. The VBM consists of an enclosed shelving system with a movable mast running down a center aisle for picking and storage of totes. The unit is designed to be able to work ahead of the operator and queue up the next pick for maximum throughput of the system.

Download the Vertical Buffer Module Quick Facts PDF

Totes can be delivered to an ergonomic turntable picking station or can be automatically handled via inbound and outbound conveyor. The machine can also be configured with a manual station for replenishment of totes during picking operations. Picking never needs to be interrupted for replenishment activities.

Multiple units can be connected via conveyor and totes can be delivered to remote picking stations. The system is designed to be modular, scalable and highly energy efficient.

|

"The Vertical Buffer Module (VBM) is a game-changer for modern warehouses seeking efficient solutions for smaller-scale applications. Its modular and scalable design, combined with ergonomic picking and uninterrupted replenishment capabilities, makes it an ideal choice for operations that require flexibility without the high cost of larger systems. By enabling seamless integration with conveyors and remote picking stations, the VBM offers adaptability and productivity efficiencies that pave the way for smarter, more productive warehouses." Cal Bowers Sr. Director of New Business |

Robotic Delivery ASRS Technologies

#6 Robotic Shuttle Systems

This dynamic storage solution uses robotic shuttles to travel independently from level to level, riding on narrow rails at each storage level. They retrieve stored items at high speeds, with throughput ranging from 200 to 700 lines per hour. Handling cases, totes or trays weighing from 35 to 110 pounds, this type of goods-to-person, automated storage system can deliver increasingly higher throughput (300 - 1,000 lines per hour) based on the number of robotic shuttles inducted into the system.

These systems are modular, scalable and flexible—meaning they can be expanded with minimal structural modifications as business needs change.

For more information on robotic shuttle systems, check out this deep-dive article by MWPVL.

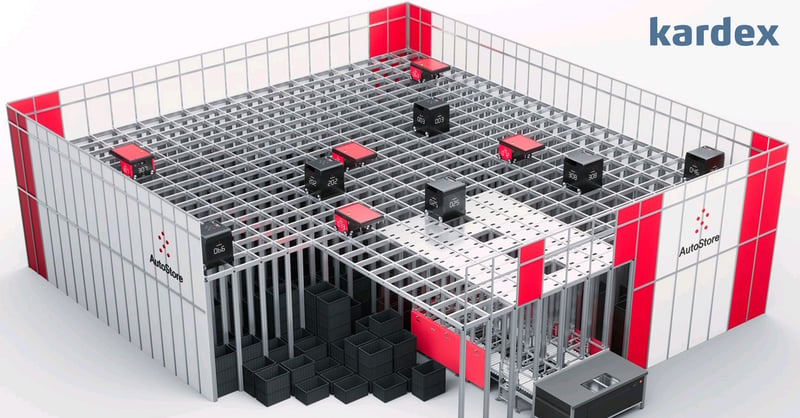

#7 Robotic Cube Storage

Using the newest type of ASRS technology, robotic cube storage, all inventory is placed into bins that are neatly stacked on top of each other inside a cube. Smart robots work at the top of the cube to shuffle, sort and retrieve bins and deliver them to a workstation (port) as needed.

|

“Companies are increasingly turning to robotic cube storage systems to keep up with rising consumer expectations for fast and accurate delivery. Because these systems optimize space and streamline picking operations, they ensure that fulfillment centers can handle growing order volume while maintaining flexibility in managing a wide variety of SKUs. It’s basically a no-brainer for any high volume warehouse needing to scale for the future.” Joe Elie |

All robots work independently on the same grid (cube), wirelessly connected to the system and charge themselves when not in use. The controller and software act as the command center providing traffic algorithms and keeping track of everything. Robotic cube storage systems are modular - it's easy to add robots or workstations as throughput demands fluctuate. The system is also configurable as the grid can be built to any shape or size warehouse.

Learn More about Robotic Cube Storage

#8 Floor Robots (AGVs/AMRs)

Why go to the shelving when the shelving can come to you? This solution stores inventory on portable storage shelving that is retrieved and transported from storage to an operator access area by a fleet of autonomous, mobile robots. After the operator selects the required item or items from the shelf, the robot returns it to storage.

Ideal for slow to medium velocity inventory, throughput ranges from 100 to 300 lines per hour and is dependent on the number of robots in the system. Throughput can also be expanded easily with the addition of more robots. The standard weight capacity of 1,000 pounds per shelving system can be increased with the heavy-duty model handling up to 3,000 pounds per shelving unit.

There are two types of floor robots - AGVs and AMRs - and while the technologies are similar, there are some key differences. Automated guided vehicles (AGVs) are good for repetitive and consistent tasks. They are guided by wires, magnetic strips or sensors that are put onto the facility floor. They then travel only along the marked, predetermined routes. While they can detect obstacles in the route, they are unable to travel off the predetermined path to navigate around them.

Autonomous mobile robots (AMRs) have onboard software intelligence allowing these floor robots to navigate through a facility using maps (similar to how the GPS in your car works). Using the onboard maps combined with sensors and cameras, an AMR can survey the area and plan the best route to get from point A to point B in the warehouse while navigating around obstacles in its path.

For more on floor robots, check out this MHL article.

|

"AMRs are quickly becoming an essential feature of the modern material handling landscape. They tick off all the right boxes: efficient, flexible, and scalable. These attributes make them ideal for any industry where demand shifts are the norm." Steve Simmerman |

Which Type of Automated Storage is the best fit for your operations?

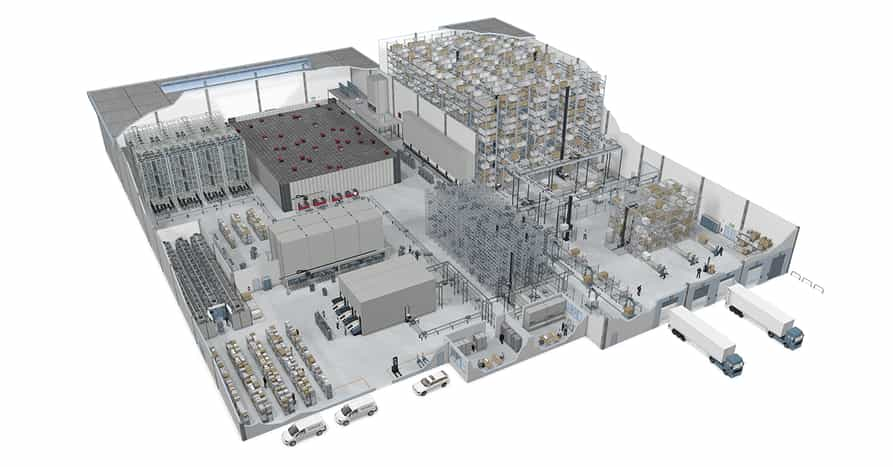

The ideal solution will often include two or more different goods-to-person automation technologies, strategically matching the system to the different inventory profiles and handling characteristics required to create a complete, hybrid solution.

Check out our complete library of Buyer's Guides in our resource center: Vertical Storage Systems | Vertical Lift Module vs. Vertical Carousel Modules | Vertical vs. Horizontal Carousel Modules | Vertical Lift Module vs. Vertical Buffer Module | Miniload vs. Vertical Buffer Module

For more information about Automated Storage and Retrieval Systems, check out our Intro to ASRS post.

Prepare for 2025 with these 25 Expert Thoughts on Six Key Warehouse Automation Trends for 2025.