3. Improved Pick Accuracy

Each step within the picking process is an opportunity for human error. The more manual the process, the greater the opportunity for error.

ASRS systems integrate with a variety of light-directed picking technologies and integrated message centers that communicate pick information to the operator for high pick accuracy. Together, these systems indicate the precise area within the carrier of the item to be picked, display the part number or description, pinpoint the exact location, direct picking (or storage for replenishment) and indicate the required quantity. These visual picking aids reduce picking errors and increase accuracy up to 99.9%.

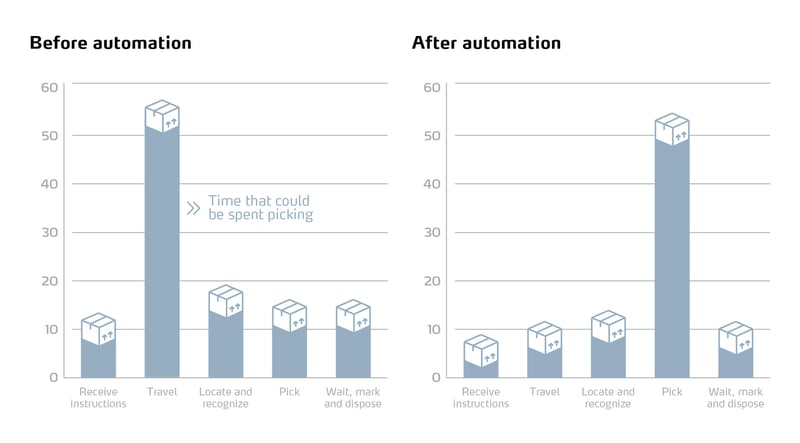

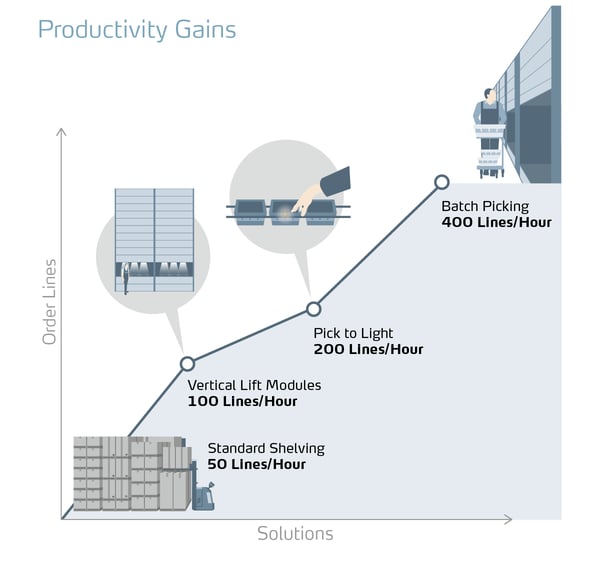

4. Increased Pick Throughput

In a manual operation, pickers often fill just one order at a time, translating into pick rates of approximately 50 lines per hour. ASRS technologies utilize the goods to person delivery concept to eliminate walk and search time to double throughput. Integrating pick to light systems that direct the operator to the exact location of the pick double the throughput rates again.

Using batch picking—a process that groups together orders with a common item or items—integrated inventory management software sequences the picks for completion in a single rotation (or cycle) of the unit. Multiples of the same items are picked then delivered to a nearby workstation for sorting into appropriate orders. Because multiple orders can be filled at the same time, throughput rates can be doubled again.

5. Greater Inventory Control

ASRS solutions house inventory within a fully enclosed system; providing safe, secure and controlled inventory management. The system can be configured to permit only authorized personnel access to stored inventory through a personal login and password. This allows missing or misplaced goods to be tracked back to a specific individual. This enhanced level of accountability and security eliminates inventory shrink and its negative impact on the bottom line.

Additionally, items are kept clean and protected from exposure to dirt, dust and other environmental contaminants. Not only does this extend their useful life, but also reduces the amount of products or components that must be scrapped due to damage.

Machines can be interfaced with a facility’s warehouse management system (WMS) and enterprise resource planning (ERP) systems allowing you to closely monitor stock levels in real time—and potentially eliminate physical counts—to reduce the amount of inventory they must have on hand. FIFO (first in, first out) or LIFO (last in, first out) picking processes can also be implemented for better inventory turn.

6. Improved Ergonomics

Every item stored in an ASRS can be delivered to the operator at an optimal ergonomic height - also called the “Golden Zone” (between a user’s shoulder and knees). Shelves, trays or bins of items are presented in easy reach, eliminating bending down to retrieve an item stored low, or stretching up to grab an item stored high. With some ASRS units, the addition of a lift table can be necessary to achieve this ergonomic benefit. This substantially reduces the risk of worker injury, absenteeism, insurance premiums and claims for worker’s compensation.

Further, by delivering items to the operator and eliminating walking through rows of shelving operator fatigue is minimized.

In Summary

So there you have it, the details on how an ASRS can save you floor space, reduce your labor, minimize picking errors, speed your pick rates, provide better inventory control and create an ergonomic work environment for your employees.

For more on Automated Storage and Retrieval Systems, check out our Intro to ASRS post.