How Spare Parts and Maintenance Kits Can Bridge the Gap for OEM Equipment Providers

In the face of ongoing economic uncertainty and higher interest rates, businesses worldwide are taking a cautious approach to Capital Expenditure (CapEx) spending in 2023. While some industries, such as gas and oil, are increasing their CapEx investments, others are postponing purchases of new machinery and equipment. But these assets, as they continue to age, are still a critical part of servicing the end customer so companies need to find innovative ways to make do with their existing resources while CapEx spending remains on the back burner. How? Keep it operational through increased preventive maintenance and a healthy stock of spare parts.

For machinery and equipment providers who have seen their new orders decrease in 2023 and are frustrated by the delays in the selling cycle should strongly consider an increased focus on replacement and maintenance spare parts delivery at the highest service level, ensuring customers with aging equipment have access to the parts they need quickly. The ability for OEMs to ship/deliver parts quickly (i.e., same day shipment) won’t be lost on their end customers when capital spending starts again.

What is Driving the Reduction in Global Capital Expenditure Spending: Amidst mixed mid-year reports, it is evident that CapEx spending is experiencing a decline in 2023, with projections indicating a notable reduction compared to the previous few years. A combination of economic uncertainty and record-high interest rates has led many companies to approach capital investments cautiously.

The Implications for Spare Parts and Maintenance Spending: To bridge the gap, companies are turning to their facilities teams to focus on keeping existing equipment operational. This approach necessitates an increase in preventive maintenance and the maintenance of a ready stock of spare parts. As aging equipment remains in use until CapEx spending resumes and replacements are approved, the demand for spare parts, including preventive maintenance kits, is expected to rise and remain high for the foreseeable future.

The global reduction in capital expenditure spending for new manufacturing machinery and equipment is reshaping spending patterns across industries. OEMs that can successfully fulfill spare parts for their customer base in a timely manner will be well-positioned to keep customer satisfaction high as we navigate through these uncertain times and allow CapEx spending requirements and levels to return to normal.

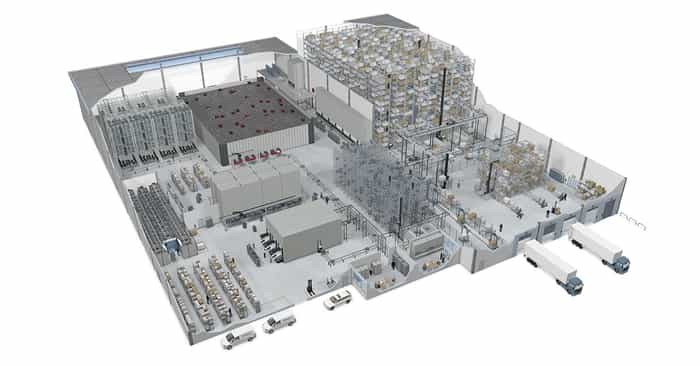

If you are reshaping your spare parts and maintenance kitting fulfillment operations, but storage capacity and labor inconsistencies have you concerned - contact us today to discover how our ASRS solutions can help!