Implementation

Once the machine is installed, there are costs associated with implementing the new technology into your existing processes. These costs are highly dependent on the size of your operations and the depth of the integration you are striving for, but I want to be thorough.

Moving beyond a stand-alone ASRS product into more of a total solution has major benefits, but can come with added costs. The first is what I like to call the machine interaction cost – how items will go into the ASRS and how they will come out of the ASRS. Will a person be responsible for getting items in and out of the ASRS? If so, do they require an ergonomic hoist, a manual transport cart? Also consider supporting technologies – such as light or voice directed picking technology, barcode or QR scanning, etc. Will the ASRS machine interaction be highly automated with an automatic conveyor transport or robotic picking?

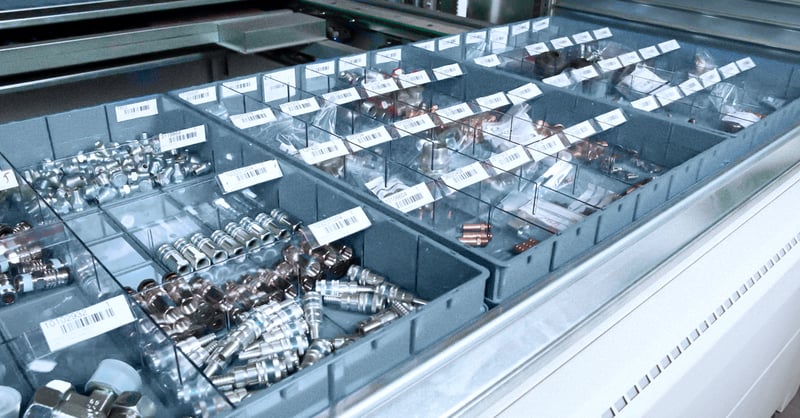

Also consider how the parts within the ASRS will be organized. Most often ASRS solutions require totes, bins, and dividers to most efficiently use the space within the system and get optimal productivity rates. These can be included in the machine costs, but sometimes are not – so be sure to account for these.

Then it’s time to load parts into the ASRS. Do not underestimate the time and cost of the parts move. This is often overlooked and brushed aside with a “we can do it ourselves” attitude. While I applaud the enthusiasm; it’s takes many painstaking hours, days (sometimes weeks) to configure the locations with the ASRS and then physically move parts from one system to another. In addition, when replacing an existing solution, parts often have to be moved to temporary storage and then into the ASRS. With a clear and well thought-out plan; a parts move can happen in a weekend with minimal impact to your operations. There is definitely a cost associated with a parts move, but it’s often one worth paying someone else to do it for you.

ASRS implementation can be pretty simplistic or extremely complex depending on your level of integration. It might be in your best interest to have an expert advisor from the ASRS manufacturer project manage the entire ASRS implementation for you – including the machine interaction process, planning and executing the parts move and configuring initial KPIs and reporting.

Ongoing Costs

Initial basic user training is often included with the machine or software costs; but it’s important to plan (and budget) for regular updated training. As the users get comfortable with the new ASRS technology they will benefit from a short refresher training a few months after initial installation – now with a working understanding the new technology and processes. This is also true for organizations with high turnover. A “train the trainer” user philosophy can work well, but don’t overlook the benefit of some occasional updated training.

For the future success of the ASRS, it’s critical you budget and plan for the recommended scheduled preventative maintenance as suggested by the manufacturer. Most often, preventative maintenance is included (and required) by the manufacturer within the warranty phase. After the warranty expires, it’s up to you to keep the technology maintained. Regularly scheduled preventative maintenance will help to reduce or eliminate unplanned downtime.

“If you don’t plan for maintenance, your machine will plan it for you.”

For optimal efficiency, inventory within the ASRS should be regularly analyzed and re-slotted within the system. Over time you will find that inventory that was once a fast moving “hot” SKU is now a slow mover (think beanie babies). As the pick frequency of that SKU changes, so should its location with the ASRS. Slotting philosophies can vary slightly between automated storage technology – but you always want fast moving inventory in the most accessible locations. While there isn’t a hard cost associated here (however your time is a soft-cost!); be sure to plan a regular slotting review (monthly, quarterly, semiannually) to keep your ASRS investment running at peak performance.

Final Thoughts

There’s a lot to consider when it comes to ASRS – the choices are endless. The good news is with the right combination of ASRS technology, software and implementation you can find a solution that’s exactly what you need.

Once you've determined the perfect system and the associated cost, the next question is even more important. How do you justify the investment? Our Cost Justification Tool will go along way in helping you determine exactly this.