In the dynamic and demanding world of warehousing and logistics, businesses are always on the lookout for innovative ways to streamline their operations and improve efficiency. When it comes to effective inventory management, one technology stands out - Automated Storage and Retrieval Systems (ASRS).

ASRS technologies, also known as goods-to-person systems, are designed to automate and optimize the storage and retrieval of inventory providing real-time inventory control and tracking, reducing stockouts and overstocks and increasing overall inventory accuracy. ASRS inventory management is an effective, efficient, and modern solution for warehouses looking to streamline their inventory processes.

Improved Accuracy and Precision

One of the key benefits of ASRS inventory management is the improved accuracy it brings. Automated systems minimize the potential for human error, which can lead to misplaced items, inaccurate inventory counts, and other costly mistakes. By utilizing a combination of robotics, barcodes, and sophisticated software, ASRS technology ensures that every item is precisely tracked, stored, and retrieved.

Increased Productivity

ASRS solutions dramatically increase the speed and efficiency of inventory management processes. With conventional manual systems, employees spend a significant amount of time moving around the warehouse, searching for items, and conducting manual counts. In contrast, ASRS systems quickly and efficiently handle these tasks, allowing staff to focus on more complex or high-value tasks. This leads to substantial gains in productivity and operational efficiency.

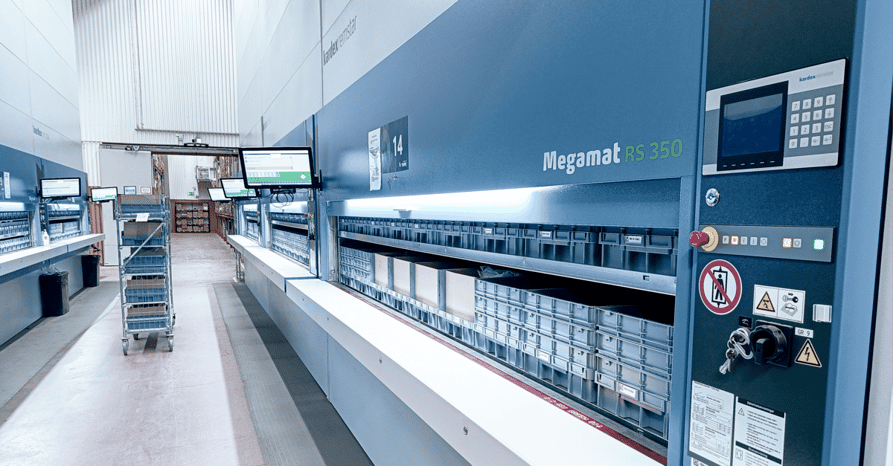

Enhanced Space Utilization

ASRS systems are designed to make maximum use of vertical space within a warehouse. This allows businesses to store more items in a given area, reducing the need for costly expansions or relocations. Furthermore, by eliminating the need for wide aisles to accommodate forklifts and other equipment, ASRS technology can significantly improve space utilization in your warehouse.

Reduced Labor Costs

Another significant advantage of ASRS inventory management is the potential for reduced labor costs. As these systems automate much of the work traditionally performed by manual labor, the need for a large workforce is reduced. This not only reduces labor costs but also minimizes issues related to workforce availability or turnover.

Scalability and Flexibility

ASRS systems are highly scalable and flexible, making them ideal for businesses with evolving needs. These systems can easily be expanded or reconfigured to accommodate growth or changes in inventory. This scalability ensures that your investment in ASRS technology will continue to provide value as your business grows and evolves.

Integration with Other Systems

ASRS solutions can be easily integrated with Warehouse Management Systems (WMS), Enterprise Resource Planning (ERP) systems, and other software used in inventory management. This allows for seamless coordination and information sharing between different systems, leading to more comprehensive and effective inventory management.