2. Reduce Warehouse Floor Space Costs

What is the value of additional floor space?

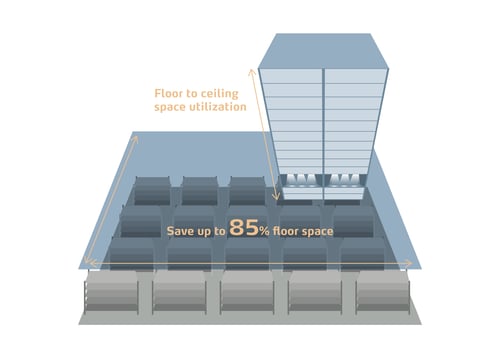

Automated storage equipment opens your facility’s floor space by utilizing your building’s height to store inventory overhead. This eliminates both the footprint required by static shelving and pallet rack, as well as the aisles required to access them. Further, automated systems utilize tightly configured totes, bins, dividers, drawers and specialty holders. These components separate and organize the maximum number of stored items possible in each of the system’s trays or bins.

To further maximize every square inch of storage space within the automated system, inventory management software is integrated. Programmed to dynamically manage the cube space within the automated storage system, the software keeps shelves holding the inventory as tightly compressed as possible. Because of this capability, automated storage systems eliminate the empty reach-in space required by shelving. As a result, the equivalent amount of inventory held in 120 bays of static shelving can be condensed as shown below.

| System | Wasted Floor Space (based on 20' ceiling) |

Wasted Unit Density |

| Shelving | 70% | 50 - 70% |

| Drawers | 80% | 60% |

| Flow Rack | 70% | 60% |

| Pallet Rack | 70% | 60% |

| Horizontal Carousel Module | 30% | 25% |

| Vertical Carousel Module | 10% | 20% |

| Vertical Lift Module | 10% | 10% |

| Vertical Buffer Module | 20% | 30% |

The value of the freed-up floor space depends on its new use. Open space can be used to store larger volumes of the same SKUs or accommodate expanded inventory of new SKUs. Alternatively, the opened-up areas can be repurposed for other, revenue generating processes. Additional light manufacturing for customization, kitting of related items, or enhanced quality control processes are value-added activities that can positively impact the bottom line.

3. Reduce Picking Costs

Are picking operations fast enough to meet customer demand?

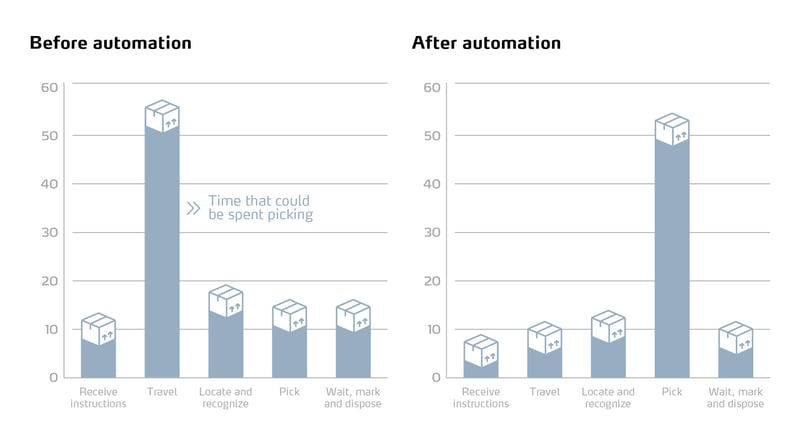

Operators picking manually are often restricted to filling one order at a time. Limited by paper pick lists and a lack of picking optimization software, they may visit the same popular SKU pick faces multiple times in a day. For a facility with static shelving or pallet rack, this translates into pick rates of approximately 50 lines per hour.

Alternately, an automated storage and picking solution facilitates batch picking. The process groups orders with a common item, or items, together. Multiples of the same item are picked, then sorted to their appropriate orders for shipping at a nearby workstation. This means multiple orders can be filled at one time—up to 750 lines per hour, as shown here.

| System | Bag & Tag (lines per hour) |

Pick & Toss (lines per hour) |

| Shelving | 10 - 35 | 30 - 75 |

| Drawers | 10 - 35 | 30 - 50 |

| Flow Rack | 25 - 45 | 75 - 150 |

| Pallet Rack | 35 - 60 | 95 - 200 |

| Horizontal Carousel Module | 75 - 200 | 225 - 750 |

| Vertical Carousel Module | 50 - 175 | 150 - 225 |

| Vertical Lift Module | 50 - 150 | 125 - 175 |

| Vertical Buffer Module | 50 - 175 | 125 - 200 |

Because automated storage technologies utilize integrated inventory management software, batch picks can be completed in a single rotation, or cycle, of the unit. Batch picking with an automated system eliminates bottlenecks associated with waiting for one last item to complete an order or finish a manufacturing process. Batch picking can also be used to prioritize orders by importance or by inventory availability. This enables customer order cut-off times to be extended, increasing a company’s competitiveness and customer satisfaction. Time is money when it comes to picking orders. Therefore it's important to avoid unknown inventory shortages. Be sure to keep an eye on inventory regularly. Learn more about inventory shrinkage.

4. Reduce Workplace Injuries and Absences

What is the cost of an absent, or injured, worker?

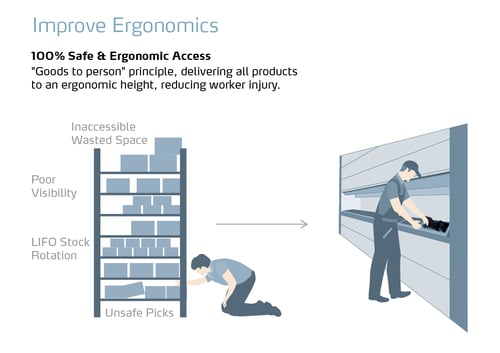

Manual picking operations utilizing shelving or pallet rack for item storage can require a picker to reach, bend, lift, twist, stretch, push or pull to retrieve inventory. The storage units are characterized by:

- Wasted space due to inaccessibility

- Poor visibility of products in the back

- Last-in/first-out (LIFO) stock rotation

- Unsafe picks due to storage position (height or distance)

To avoid potential injury, it is often recommended that workers pick items from the 'golden zone,’ which extends from the belt height to the shoulder height of the average individual. Items within this zone can be grabbed or moved without either stretching or bending.

In contrast, automated storage systems present stored items at the proper ergonomic, golden zone work height. This creates a safe working environment that minimizes injuries from bending, reaching and stretching. Further, walking and climbing are no longer necessary. Not only does this reduce fatigue, but also the chance of worker injury is substantially lessened. In turn, absenteeism, insurance premiums and claims for worker’s compensation will be reduced.

To further safeguard workers, a variety of safety systems are integrated in the automated systems. Light curtains, emergency stop buttons, presence-detecting safety mats, software-enabled access, automatic shutter doors and photo eye sensors prevent pinch points and entrapments while a worker is interfacing with the machine.

5. Reduce Picking Errors

How much does a picking error cost?

The cost of a picking error includes not only the cost of the item, but also the expenses associated with shipping the item back, processing it upon receipt, returning it to inventory and loss of customer satisfaction. Further time is lost in correcting the mistake by picking, packing and shipping the correct item back to the customer.

An estimated 35% of facilities experience ongoing mispick rates of 1% or more. Although 1% sounds like a slim margin for improvement, it adds up quickly.

Because automated storage systems incorporate advanced picking and real time inventory tracking technologies—such as light-directed indicators that pinpoint the precise SKU location and quantity to be picked—picking accuracy increases up to 99.9%. The storage system mitigates human error and produces better inventory control. Not only will this contribute to a dramatic reduction in picking mistakes, but it will result in tremendous cost savings. Further, customer satisfaction will improve, likely leading to an increase in repeat purchases.

For More: 5 Pick to Light Technologies for Laser Accuracy